BRASTEMP Inverse maxi

LAR | Staff Industrial Designer

A completely new refrigerator platform, and Whirlpool LAR's largest refrigerator platform yet.

One year into the company, I was given the opportunity and challenge to design from scratch the largest yet platform for LAR, 100% developed and manufactured in Brazil. The project required the company to make its largest factory investment in ten years. It was also the company's fastest-developed project, in a record time of 1.5 years.

The design process entailed a lot of user research - visiting consumers’ homes to understand storage habits, then testing solutions in lab - internal layout ideation, 1:1 cardboard prototyping, and high-fidelity, realistic full product prototypes.

Brastemp Side-Inverse created a new market segment in Brazil, was exported to all of Latin America, and forced competitors to follow suit. The platform served as a base for Brastemp Inverse Maxi.

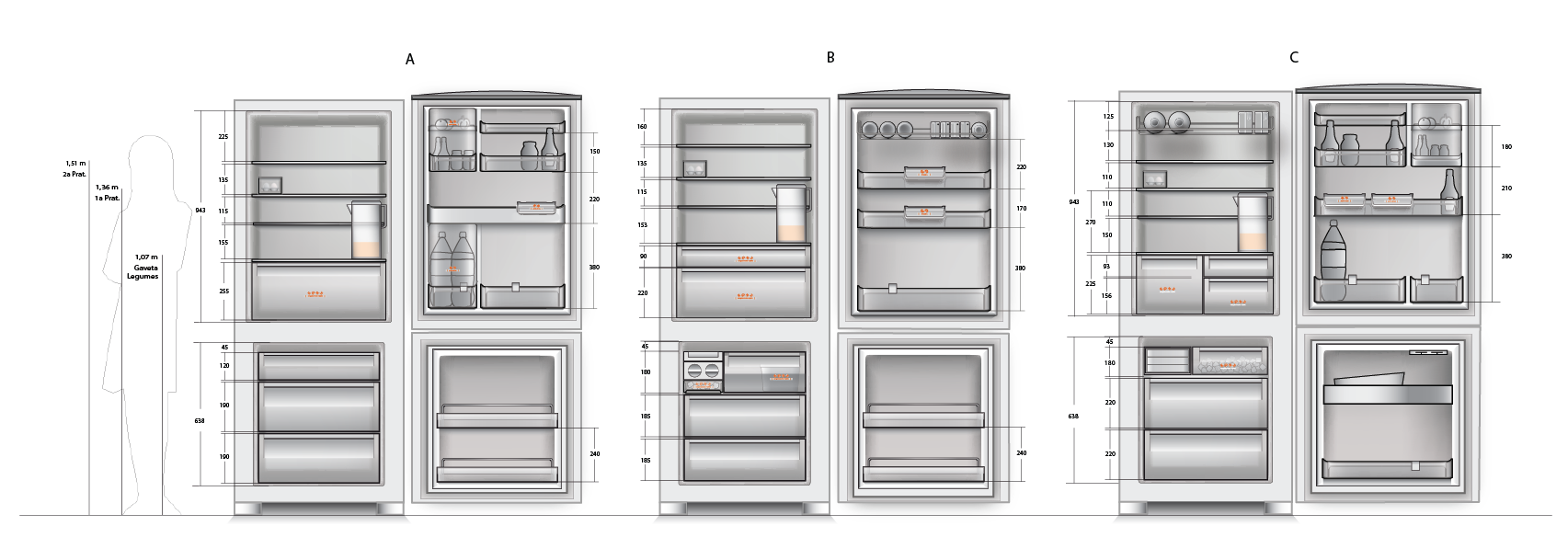

Ergonomics is crucial when developing a refrigerator interior. As part of the process, we also documented most common shopping items in Brazilian households. Once this list was done, several internal layout configurations were explored, making sure we were creating room to store everyday-use items, flexibility for occasionally large items, as well as specific features for new items in the market.

INTERNAL LAYOUT IDEATION

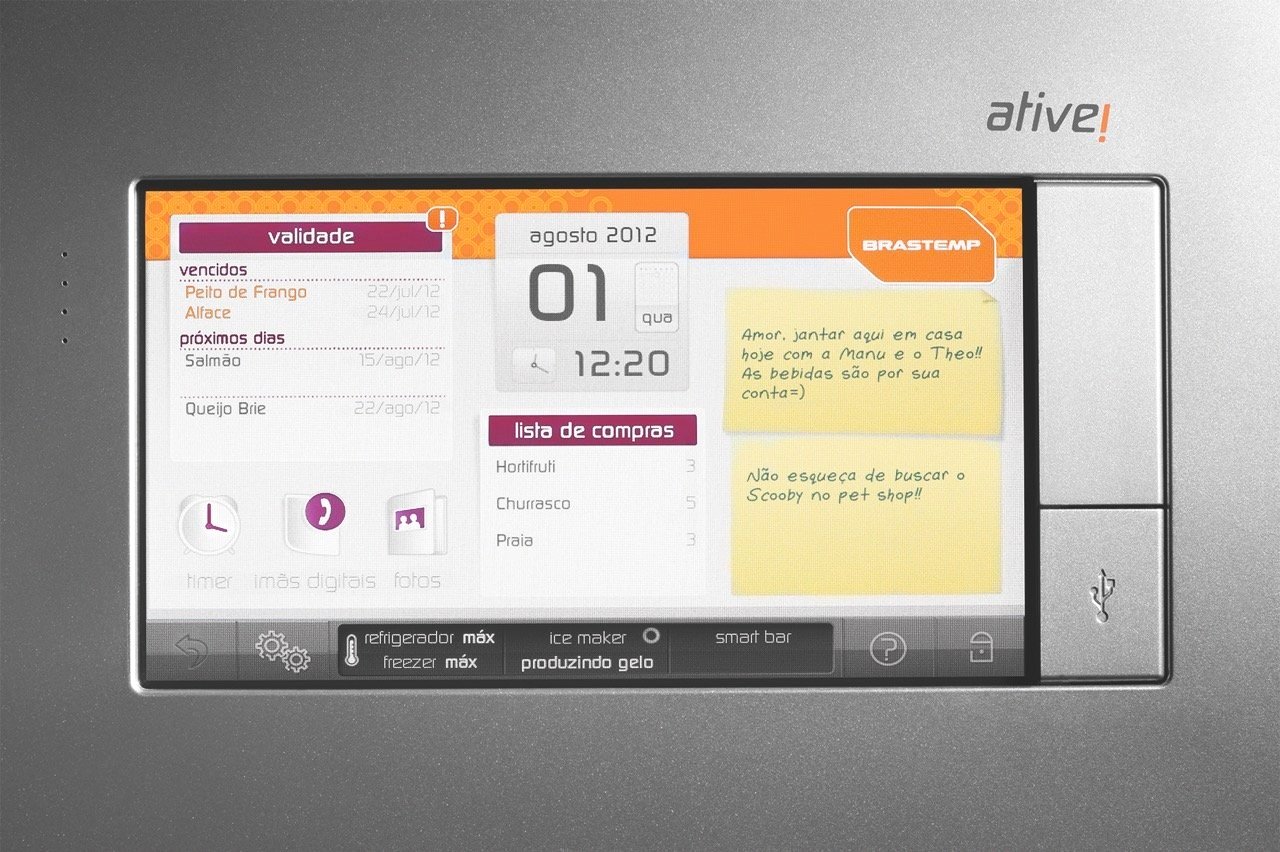

EARLY CONNECTIVITY

Shopping list export to phone via QR code

Back in 2013, we developed the first on-appliance smart UI, with features pertinent to household activities and food inventory, with QR codes being the only feasible way to connect the product to user'’ daily activities, off-fridge.

We accomplished great progress in interaction design for refrigeration, the technology development in-house being carried over to all subsequent generations of products, including Brastemp Side-Inverse

"Virtual Magnets”

Home Screen with key shortcuts

Image Credits: Histórias de Casa